Taishan Academic Forum - “Frontiers of Lubrication Technology of High-end equipment” - 2022 Eastern Tribology Academic Forum was successfully held

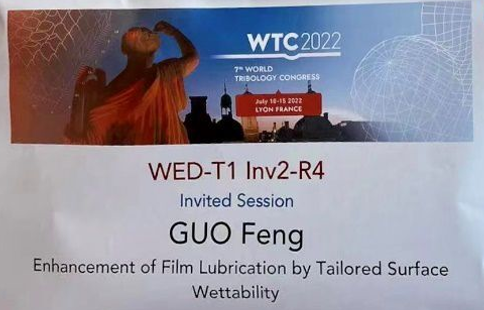

Prof. Feng Guo was invited to give an invited lecture at the 7th World Tribology Congress

Symposium on the Joint training of postgraduates by the School of Mechanical and Automotive Engineering of Qingdao University of Technology and Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences

Latest Papers

Experimental and theoretical studies have been completed in this paper to investigate the interface effect in the lubrication performance of a step slider bearing. Oleophobic fluorine-containing diamond-like carbon (F-DLC) coatings were prepared on the step slider to provide low affinity to lubrication films. With an optical slider bearing test rig, it is revealed that the F-DLC coating presents an increase in the film thickness/load-carrying capacity and a decrease in the coefficient of friction (COF), which is quite different from the common idea that both the load-carrying capacity and the COF are reduced at the same time. Contact angles measurement on the step slider shows that the affinity to the lubricant of the inlet step surface is lower than that of the outlet land, which can be attributed to the rougher surface of the step surface by the laser ablation. Theoretical analyses show that various interfacial slip velocities on the inlet step and the outlet land can generate different change in the load-carrying capacity and the COF. When the step surface presents lower interfacial slip velocity of the film than the land surface, increase in load-carrying capacity and decrease in the COF can be theoretically found to support the experiments finds.

In this paper it was demonstrated that a small quantity of silicone oil could be employed as a secondary lubricant to assist water lubrication when there appear short-time sever working conditions. With a deliberately fabricated fiber-guide nozzle a short-time injection of silicone oil to water lubricated block-on-ring contact in the mixed lubrication could reduce friction of the contact markedly. With increase of the ring speed the friction reduction ratio decreases first and then slightly increase thereafter. Measurements of the wear track displayed more wear reduction under higher ring speeds and larger viscosity. It was proposed that the friction and wear reduction could be attributed to the water-excluded lubrication film formation in the whole contact zone by silicone oil, which was validated by optical interferometry measurement of the lubrication films. In addition, through fluorescence technique it was found that water environment can reduce the wettability of the silicone oil on the lubrication track so that the oil replenishment on the track is enhanced and the film thickness increases.

Under limited lubricant supply condition, the lubrication of a slider bearing can be enhanced by discontinuous oil droplets on the lubrication track induced by poor surface wettability. This experimental finding is contrary to the general perception that strong surface wettability favors lubricating film build up. Theoretical lubrication models with the lubricant supply in the forms of oil droplets (ModelⅠ) and uniform oil layer (ModelⅡ) are established to clarify the odd experimental observation. Results show that oil supply in the form of droplets can achieve better lubrication performance than the uniform oil layer, which are correlated to the experimental finding. The mechanism is probably due to the early film pressure initiation when oil droplets enter the bearing contact.

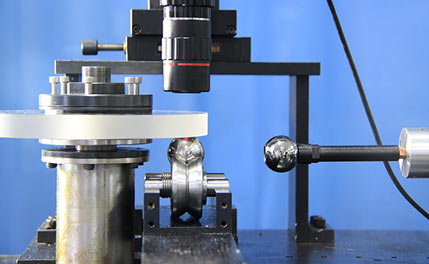

An ultra-low friction and high load capacity could be obtained on the surfaces grafted by a polymer brush even at relatively slow friction speeds in aqueous lubrication environments, which has attracted widespread attention to study the lubrication mechanism of polymer brushes; however, it has yet to be fully understood. The macroscopic tribological performance of two different polymer brushes, which were prepared by the method of “grafting to” and “grafting from” and named as PLL-g-PEG and PSPMA, respectively, were investigated. The friction results demonstrated that PLL-g-PEG obtained a lower friction coefficient than polymer brush PSPMA, which was ascribed to its unique “self-healing” behavior. The lubrication film was in situ observed and the film thickness induced by the polymer brush was measured using a laboratory set for film thickness measurement apparatus based on interference technology. It was found that PSPMA exhibited excellent lubrication performance not found in PLL-g-PEG, and two film-forming mechanisms highly dependent on velocity were revealed, which may be important to interpret the lubrication mechanism of polymer brushes in aqueous lubricants.

The water-lubricated bearing in ship propulsion system is easily impacted by sea wave shock, which is a great threat to the smooth start-up of the bearing system. Therefore, in the present research, the Euler equations, average Reynolds equation, and sea wave shock function are combined together to build the start-up model of water-lubricated bearing. The influences of amplitude, direction, and entry time of sea wave shock on the start-up performance of bearing are studied. The result shows that the shaft has a strong instantaneous vibration under the influence of friction force at the initial start-up stage, and the shock load with appropriate direction and amplitude can suppress or even eliminate this vibration phenomenon. The earlier the shock enters the start-up process, the more serious asperity contact gets, and the worse the system’s stability becomes. The increase of the shock load amplitude and the advance of the shock load entry time can help the shaft rapidly lift off. This study can provide a reference for the smooth start-up of ship propulsion system in a sea wave environment.

Effective oil replenishment to the lubrication track of a running bearing is crucial to its sustainable operation. Reliable practical solutions are rare despite numerous theoretical studies were conducted in the last few decades. This paper proposes the use of surface effect, wettability gradient, to achieve the goal. This method is simple and can be nicely implemented using femtosecond laser ablation. A periodic comb-tooth-shaped pattern with anisotropic wetting capability is devised and its effect on the anisotropic spreading behaviour of an oil droplet is studied. Results show that the comb-tooth-shaped pattern enables the rearrangement of oil distribution, thereby escalating oil replenishment to the lubrication track. The effect is due to the unbalanced interfacial force created by the surface pattern. The influence of the shape and the pitch of teeth, which are the two governing factors, on oil transport is also reported. The effects of the newly devised surface pattern on lubrication are experimentally evaluated under the conditions of limited lubricant supply. These results are promising, demonstrating the reduction in bearing friction and the increase in lubricating film thickness.

About us

Our group is now in the JLJ campus of Qingdao University of Technology, which is nestled amidst green hills and neighboring a beautiful lake. Our group, consisting of academic staff, postdoctoral fellows and research students, mainly studies the fundamentals of thin film lubrication and its application.As has been known, thin film lubrication provides an efficient way for reducing friction and avoiding wear in a tribo-pair, and plays an important role in the operation of different components, such as high speed machinery, miniature devices and artificial implants. Dedicated to area of thin lubrication film for more than ten years, our group has successfully built a series of optical systems for lubrication film measurement with new principles, which enables accurate measurement of lubrication films at thickness ranging from nano to micro-meter scales. Robust calculation codes have also been developed by our group for numerical simulation of the lubrication process, whereby some insightful details, for example, the pressure and flow field, can be obtained.With new knowledge in the studies, novel lubrication techniques have been presented and used by our partners in industries.